Gravity Separation Equipment

Washing & Screening Equipment

Crushing & Grinding Equipment

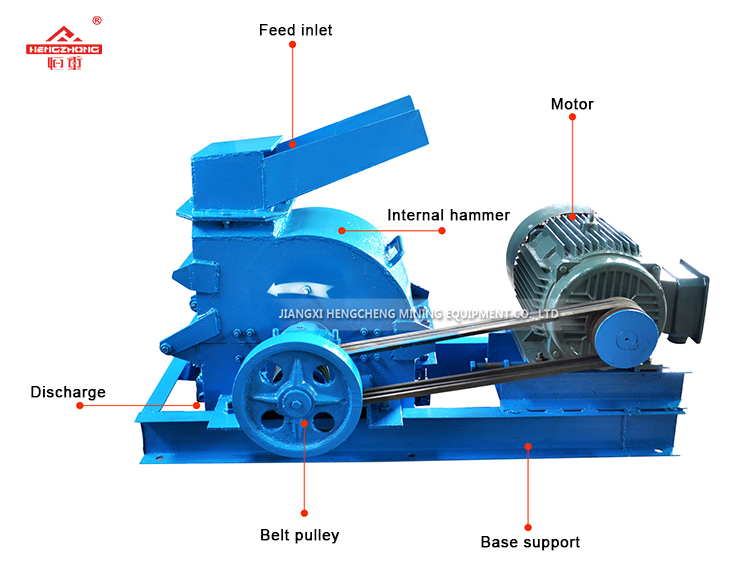

Small hammer mill (hammer mill) crushes by the collisions between high-speed hammer and materials, and its features are simple structure, high reduction ration, high efficiency, etc. The small hammer mill (hammer mill) is is suitable for both dry and wet crushing of vary brittle ores, including pyrite, magnetite, limonite, phosphate ores, coal, gravel, feldspar, alum, brick, tile, gypsum and so on.

Description

The compressive strength of the material does not exceed 150 Mpa. The surface moisture is much 15%. The machine is an important equipment for metallurgy, mining, small cement, chemical industry, building materials, coal plant and so on.

Working Principle

The motor drives the rotor rotate at a high speed through the belt, and on the rotor there are series hammers. When the materials feed into the working area of hammers, they are crushed by the rotating hammers in high speed, the minerals which are crushed into the required size can be discharged by the outlet, and become the final products; while the large size products are brought back to the crushed area by the hammers to be re-crushed until they reached the required size.

Main Features

1.Unique design, Compact structure. Seal structure, attractive appearance, avoiding dust pollution and ash leakage.

2.Adjustable feeding size.

3.Wear resisting, impact resistance. Hammer is casting with new technology, less quick-wear parts, easy to maintain.

Model | Capacity | Feeding Size | Discharge Size | Power | |

Motor | Diesel (HP) | ||||

200×500 | 1-3 | ≤50 | <2.0 | 15-18 | 24 |

300×500 | 3-6 | ≤50 | <2.0 | 18-22 | 30 |

400×600 | 5-10 | ≤50 | <2.0 | 25-30 | 45 |